With the largest capacity in Australia, we are equipped to handle massive commercial jobs such as casinos and hotels, as well as the personal attention of a one-off or home redesign.

We can plate onto any metal and are always happy to talk you through our many stunning options.

Many of our customers are metal fabricators and offer specialised services in laser cutting, bending, forming, welding and machining. These are NOT services we offer, but we are always happy to suggest a local service provider.

The services we do provide are outlined below

Stripping

We will strip any of the following finishes to allow us to do our “amazing thing”

- Anodising

- Powdercoating

- Paint

- Galvanising

- Other electroplated finishes

Polishing

Generally, an architectural finish will require mechanical polishing of the base metal to prepare it for the electroplating process. With our in house polishing team, we offer all polishing variations including, disc, course linish, fine brush polish, and mirror. Sending us polished stainless is a clever tip here to reduce finishing costs and also lead times.

Plating

The key to successful plating is ensuring that all the design intricacies are addressed at the beginning of the process. With careful planning, you can improve the final result, the cost and the overall process. Those things to take into consideration are as follows:

- General Shapes

- Tank Capacities

- Drainage

- Racking

- Substrate

- External Applications

SIZE LIMITATIONS

Astor are proud to have the largest electroplating capacities in Australia, for all base metals, our plating tanks are;

2650 x 950mm (for flat panels or 2D frames)

2650 x 950 x 450mm (for folded panels or 3D frames)

MAXIMUM HOIST CAPACITY: 75KG

Astor can finish brass base metal to 2700 x 950 x 450mm (75kg) or 3600 x 180 x 180mm

Lacquer

We offer automotive 2 pac lacquers, which are baked through in an oven at 120 degrees. Depending on the level of gloss you are aiming for, we can adjust our lacquer levels to accommodate. Our levels include:

- Matt

- Satin

- Semi-gloss

- Gloss

- Tinted lacquers for bespoke shades (note we do not offer a commercial warranty on these)

If you’re still trying to decide whether lacquer is the look for you, read our article ‘to lacquer or not to lacquer’.

Packing

We ensure that your product is protected before shipping it back to you. We provide protective and suitable packaging for local and interstate deliveries. We can also organise freight on request.

We can also arrange custom timber crates to safely deliver your components.

Fabrication advice

We have a team of qualified experts on hand to offer you advice on all your fabrication needs. On request, we will provide a FREE consultation with our experts, which will be relevant and helpful for everyone from individuals, to architects and metal fabricators. We can also provide best recommendations for which base metal to use for your use & application. In general we recommend 2D welded frames to be made from aluminium ad 3D welded frames to be made from stainless.

SUPPLY OF BASE METALS & finished products

Astor are not fabricators (although we know thousands of them) however we offer the base metal supply cut to size and finished for panels and profiles. Our finished products include but are by no means limited to:

- Tube, angles channel, flat bar in aluminium

- Tube, rod, angles, flat bar and panels in brass

- Tube, rod, angles, flat bar and panels in stainless

- Lasercut aluminium panels

- Lasercut stainless panels

- Cupboard & drawer front panels with folded returns

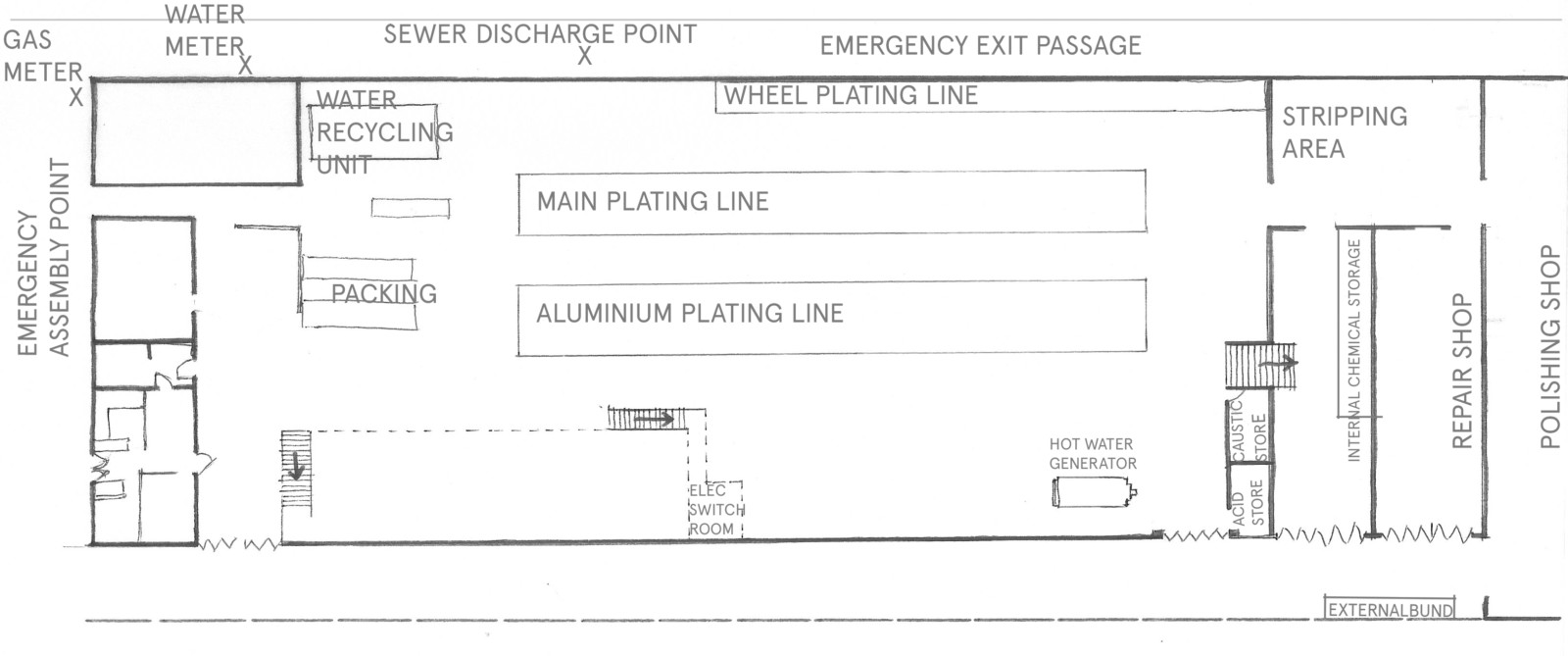

SITE PLAN