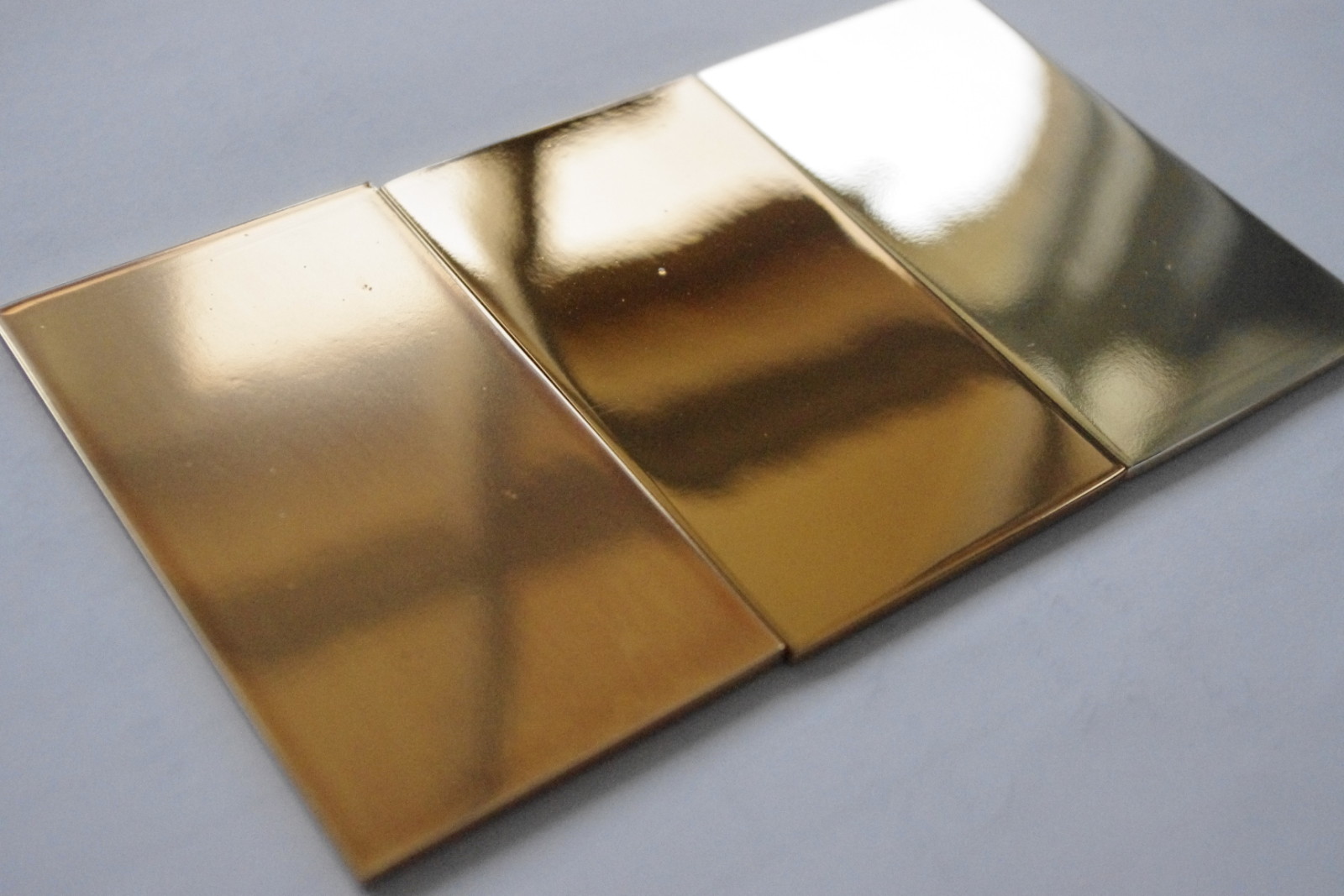

When it comes to metal finishes, there is no one option, one process or one right answer. Each metal finishing technique offers different capabilities and outcomes.

Three popular metal finishing techniques are anodising, powder coating and electroplating. Each has its strengths and limitations, and deliver different advantages for different applications.

To make each of these clearer – and make choosing one simpler – we’ve put together a (somewhat simplified) chart to compare the value, looks, application and more each option can provide you.

DOES YOUR FINISH TICK ALL THE BOXES?

Many suppliers take a ‘copy/paste’ approach to metal finishes, focusing their creative talents on the construction and making a safe bet on the finishes. This will likely be an off the shelf item that may appear to be cost-effective. But it is not always the best choice, the best value for money, or even the cheapest in the long run.

So, it pays to understand the options or risk missing out on delivering something spectacular that you never knew was possible. Here are a few of the most-common questions so you can see how each technique stacks up. If you want to dig even deeper, we’ve put together a more comprehensive comparison chart here

Start by considering the finish

Remember, these are just three techniques. We’ve only just scratched the surface of possibilities that these three – and others – can offer.

To compare further, check out our complete metal finishes comparison chart.

Regardless of the type of project, you’re undertaking, knowing your options and asking questions upfront means your finishes won’t compromise the overall effect.

Before specifying a finish or choosing a technique, it’s important to consider a wide range of factors:

- Look and visual appeal

- Use and application

- Quality

- Durability

- Lead time

- Budget

Manage expectations, avoid limitations

As the table shows, capabilities vary considerably depending on which path you take. There’s a lot to consider, but this is your project and it’s more than worth the time.

Looks are important – but not if the end product won’t perform or last as long as it’s meant to.

By understanding the parameters of different metal finishing options, you can better ensure the result and manage the expectations of those involved.

While overwhelming, the capabilities of these techniques are quite incredible – and offer almost endless possibilities for your project. Looking more closely at the options available to you can lead to a whole range of positive results:

- Right specification for application

- Enhanced visuals and prestige

- Better value for money

- Increased longevity

- Happier client

When you need to choose a technique or finish, it pays to speak to an expert. Astor Metal Finishes has been providing high-quality electroplating services for over 60 years – and can now provide over 200 unique finishes.

To find out more about specifying the right finish or whether electroplating is the right option for you, click here to contact Astor Metal Finishes. Or try out our online specification tool to discover over 200 different finishes and find the one that’s right for your project in just minutes.