With any project, there is always chops and changes, delays and disagreements, things that go wrong and things that go wonderfully right. Everyone’s aim is to minimise the bad stuff and maximise the good, achieving an amazing result with as few issues along the way as possible.

But when there’s a metal finish involved – something that is passed through many hands and affects the roles of many people involved in the project – the harder it can be to avoid issues. How do you get everyone to agree, and how can you possibly foresee delays or budget blowouts?

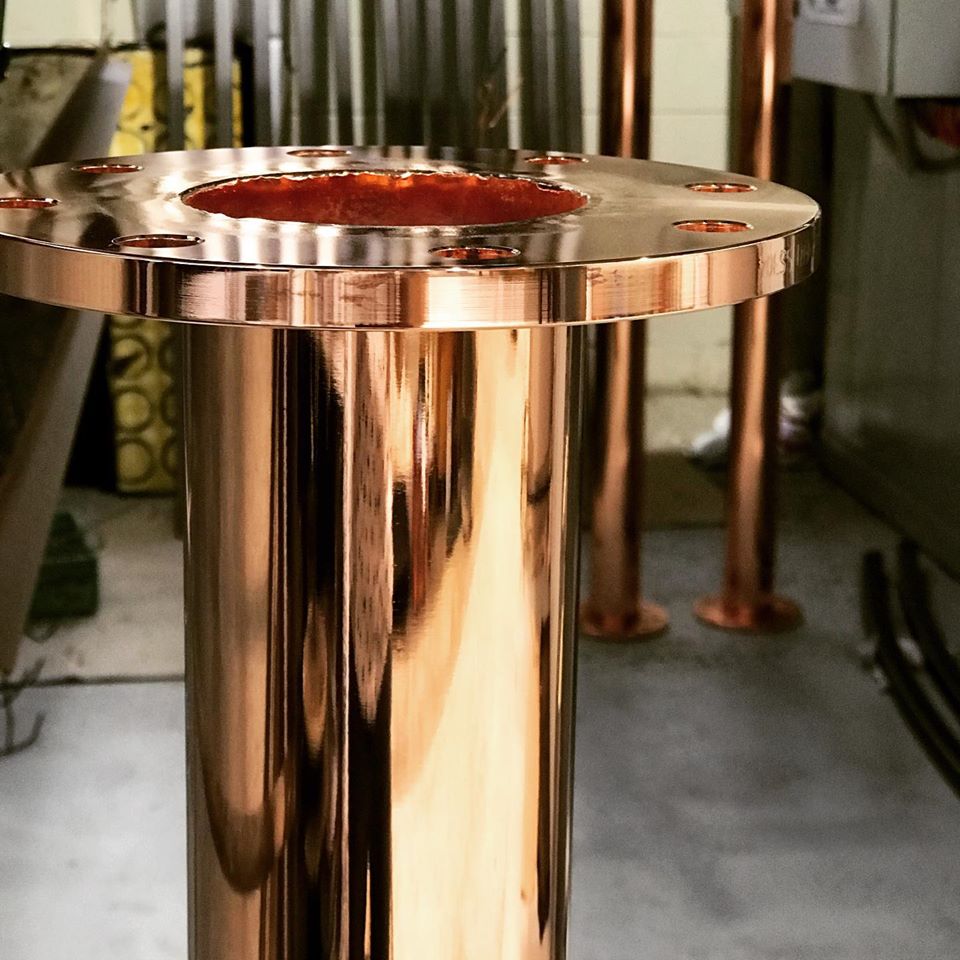

It can actually be easier than you think. Combining aesthetic with the intended application at an early stage is crucial. In the world of metal finishing, expectation and execution need to align, particularly when both the finishes and the items are often very bespoke.

Four questions to ask before you choose your finish

While metal finishes are often only one part of a much bigger project, they have the ability to throw a spanner in the works and interrupt the entire development. If your chosen metal finish is not suitable or asking too much for the intended application, or the communication around it is unclear, it can add weeks to your deadline and zeros to the end of your budget.

If you’re simply looking for a nice sample for your concept board, you don’t need to know much. But if you’re looking to develop your return brief and details of an end-product finish, that’s a whole other story.

The questions you do (or don’t) ask before you choose a finish can shape the success of your entire project. So, what should you be asking?

1. What do you want?

Do you just want a sample that looks nice? Or do you want to find the right finish for your project that will deliver on the promised deign? This is incredibly important to determine, because they’re not the same thing, and what you want will change how to approach getting it. Procuring a sample purely as a flashy piece for a proposal doesn’t need much consideration and is easily chosen.

Finding a metal finish that will actually be used for a project is much more complex. It’s not just about how it looks – it’s about the project as a whole.

2. What will it be used for?

When choosing a finish for your project, there are multiple things that will affect which is the right one for you. While aesthetics are important and will be the first things noticed about a finish, not all looks work for all projects. And that’s why you need to start asking questions.

Before you even go near looking at finishes, you need to determine:

- The application (where it will be used – outside, inside, high traffic areas)

- The project type (commercial, residential, size and quality of the finished item)

- The expectation of the finish over time

3. What are the details of finished item?

While the look and use will narrow down the search, there are more parts of the project that can affect the finish. The buildability will also affect finish choice, so it’s important to be familiar with details like:

- Metal

- Thickness

- Shape

- Joins & Detailing

4. Where are you storing this information?

Realistically, a finish should be decided on at the start of a project. But it’s not the only time you need it. While it’s usually the designer’s job to choose a finish, many other people have to work with it.

When referring back to the finish throughout the project, it’s important to know who said what, what was decided and how, and how you’ll be moving forward. This way, when different finishing requests for the same project come through, everyone is on the same page.

The wider you share your vision, the more help you’ll receive to achieve it

By taking the time to consider these questions and sharing the answers with your suppliers at the beginning of the project, you’ll be setting the whole team up for greatness.

All these details will ensure that you have a finish that will perform, look and build just as you need it to. But not only that, you will also make it easier for every other contractor and supplier to work to your brief and deliver the right outcome without issue.

You’ll now have a pretty good idea of the depth and detail needed to find the perfect finish. But even the most well-intentioned person can find it hard to do all the research, remember all the details and record all information so that it’s easily accessible and shareable.

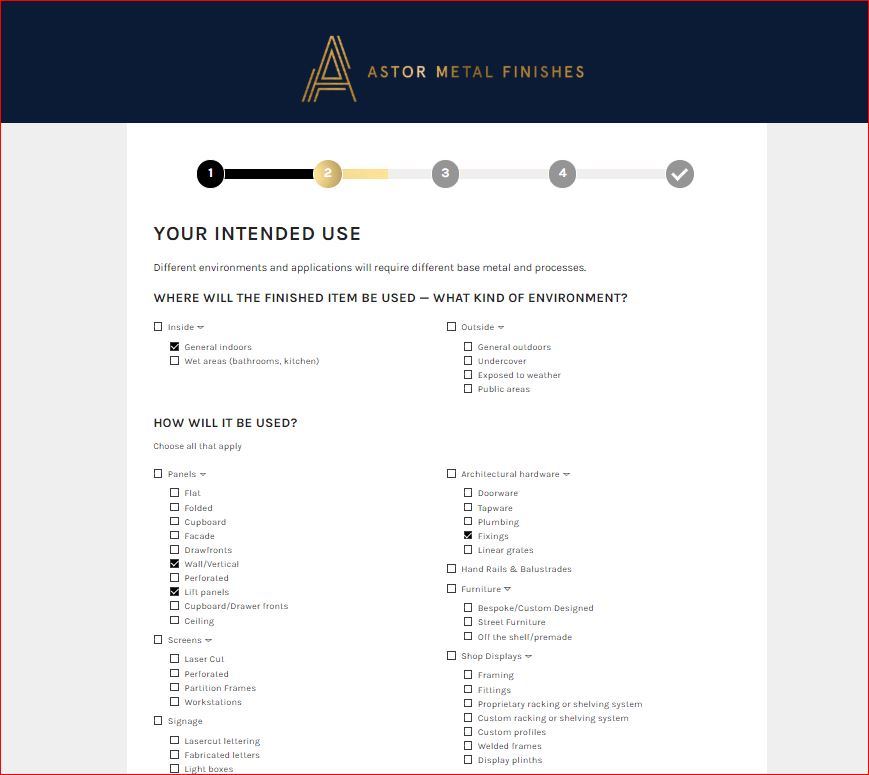

Astor’s Online Spec Tool was designed to help you out, by promoting design workshops, encouraging question asking, and storing all the details. You can then export this information and store it, email it or attach it to briefs for easy communication.

Remember – questions aren’t the enemy! The more questions you ask yourself, and the more your suppliers ask you, the better the chance your project will run smoothly, and your finished product will be perfect.

You can try the spec tool out for yourself, it takes 5-8 minutes to complete. Alternatively, have a chat to the Astor team to learn more about choosing a finish or to work through the online spec tool with you. Click here to get in touch.