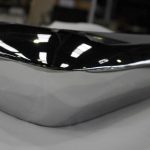

Varying finishing processes are undertaken to suit your particular application and aesthetic. Provide as much detail as possible in order to attain an accurate quote and the appropriate plating. If for exterior grade, we recommend using stainless base metal for the majority of applications and profiles. For automotive components Astor always plate with either Duplex Nickel (two coat of different types of nickel) and for poorer metals we can offer copper, nickel then chrome plating.

Plating is consistently done to AS/NZ 1192 – 2004. For further information on Surface Finishing Industry Standards, visit SAI Global, for copies of the relevant Australian Standards.

It is essential for orders and quote requests to nominate purpose and also if for exterior or wet area applications. Further TERMS, DETAILS and EXPECTATIONS are here.

- WHAT ITEMS ARE UNSUITABLE FOR POLISHING

Complex welded frames, these should be pre polished before any welding which Astor certainly can offer

Items over 30KG

Deep recesses cannot be accessed by our polishing equipment and tooling

Large panels (>600 x 600mm) cannot be mirror polished – best to use BA or Mirror stainless - WHAT ITEMS ARE UNSUITABLE FOR ELECTROPLATING

Movable parts – these will not plate successfully

Porous metal including;

Poor quality mild steel and aluminum

Cast Iron

Porous castings

Thick mild steel plate & welded tubular mild steel, if often not suitable for copper or brass-plating. We can substitute with tinted lacquers on nickel

Pinholes in welds will show up after plating, so ask your fabricator to dress the welds, and use TIG on mild steel and stainless

Braised brass joins can show up a different patina, however we can successfully plate over braises to ensure consistent finish

Items over 70kg

Please provide sketches for large folded panels which are close to our max capacities as these will need to be confirmed by technical manager for current flows, and handling

Deep recesses (more than 100mm)

Open frames are better suited to plating than close backed frames.

Items which do not drain – hollow tube frames must not have close welded sections, thus require mitre joins and/ or drainage holes

Items which do not submerge

Items which create air-pockets

Items which cannot be completely submerged into tanks

Items with rubber, plastic, glue, lock-tite, bog or other non-metal fillers,

Magnetic parts – these affect the current flows required for electroplating

Gas struts and hinges with oil or gas

Used oil or petrol tanks

Sinks (or similar items with deep recesses)

Horizontal surfaces including benchtops and work surfaces