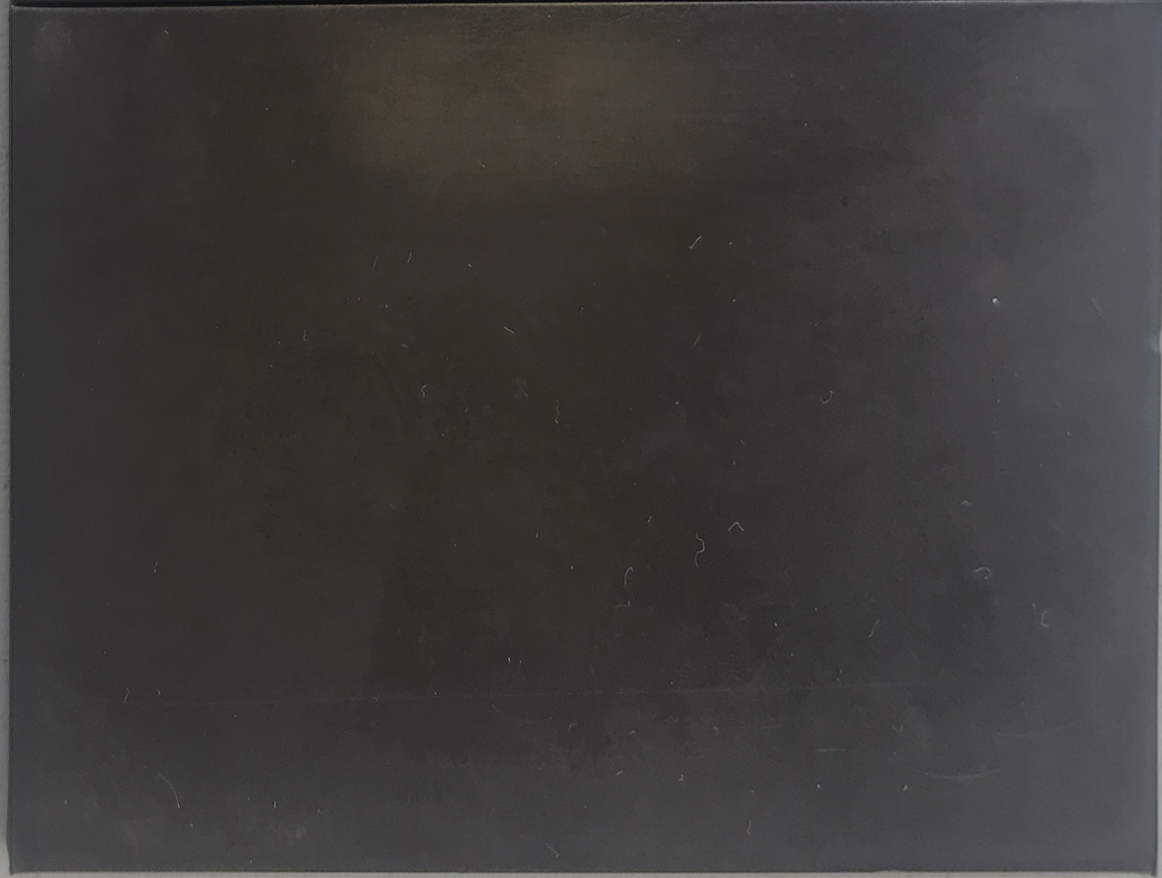

Volans (BO)

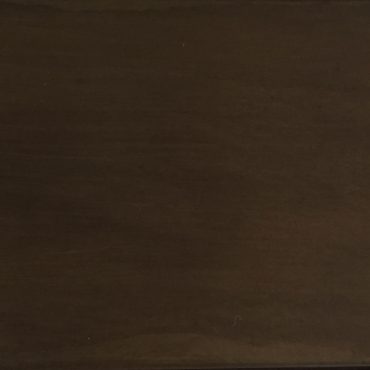

BLACK OXIDE

-

RECOMMENDED SUPERIOR FINISH Procyon Natural

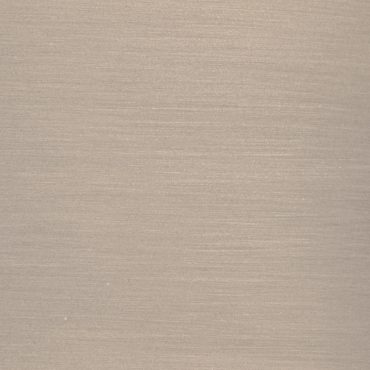

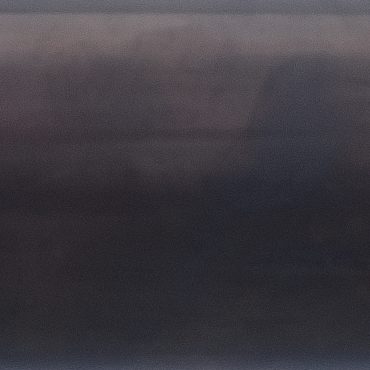

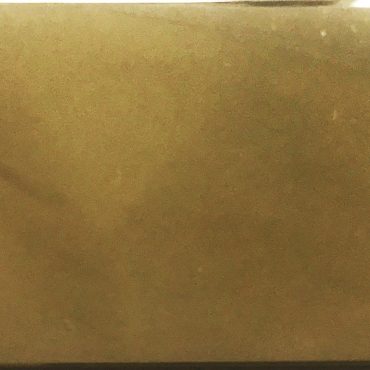

What was originally considered to be an industrial finish, is actually a finish that leading designers and architects have specified Astor to help deliver on their projects where black oxide has been desired. Often this dark finish has been teamed together with luxe fabrics, marbles, leathers & finely finished timbers throughout high-end residential and hospitality projects. This treatment of mild steel is also known as “Blackening”.

First of all, this decorative specialist mild steel finish is also known as Blackened mild steel and for that reason offers very minimal corrosion protection (it will RUST!). It is a chemical based blackening of steel at room temperature which can only be applied to a mild steel. The metal needs to be rust and mill scale (flaky oxide steel) free before application. Steps are, typically: degreaser, water rinse, conditioner, water rinse, dip in blackening solution, water rinse, dewatering oil and then air dried. To complete the look, the final finish can be specified either as oiled or with a clear 2 pac matt coating for increased durability (yet please note again if there is any contact with moisture there will be RUST).

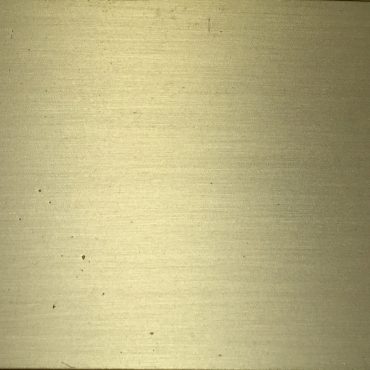

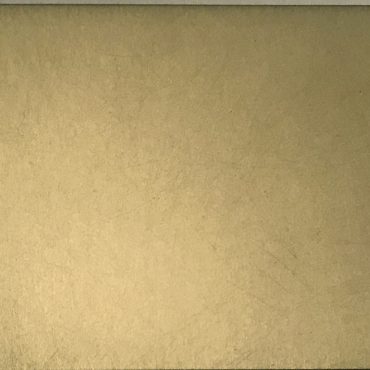

Above all, when it comes to the actual finish and the amount of brown, black or grey veins showing depends on the mild steel supplied. Any mill, fabrication marks, scratches or welds originally on the base metal will be visible under the finish. Black oxide is highly likely to leave stains and oxidise over time. Pre-treatment can also include sandblasting, linishing, or orbital sanding for variations to texture. Without a lacquer finish (or “natural” or “living” feel) it can be maintained with oil for longevity; the oil from use, abrasion and wear will limit rust forming on outer skin.